The tensile shear strength test and the metallographic studies are carried out for cu to ss em welds.

Electromagnetic impact welding of aluminum to stainless steel sheets.

Nuclear clad to tube welding stainless steel joints stainless steel telemanipulator cables crimping aluminium container covers crimping welding of closing caps metal canisters welding etc.

The application of electromagnetic em impact technique is demonstrated for welding copper cu to stainless steel ss sheets.

Results have indicated that the developed mpsw process is well suited for the welding of aa1060 aluminum alloy to 304 stainless steel.

2014 developed an electromagnetic weld pool support system for high power.

The present paper focuses on the welding of tubular mild steel to two different steel bars ferrite pearlite 1018 carbon steel and austenite 304 stainless steel using a 40 kj electromagnetic.

The objective of this work is to propose a magnetic pulse spot welding mpsw process with the aid of a field shaper for achieving the connecting of metal.

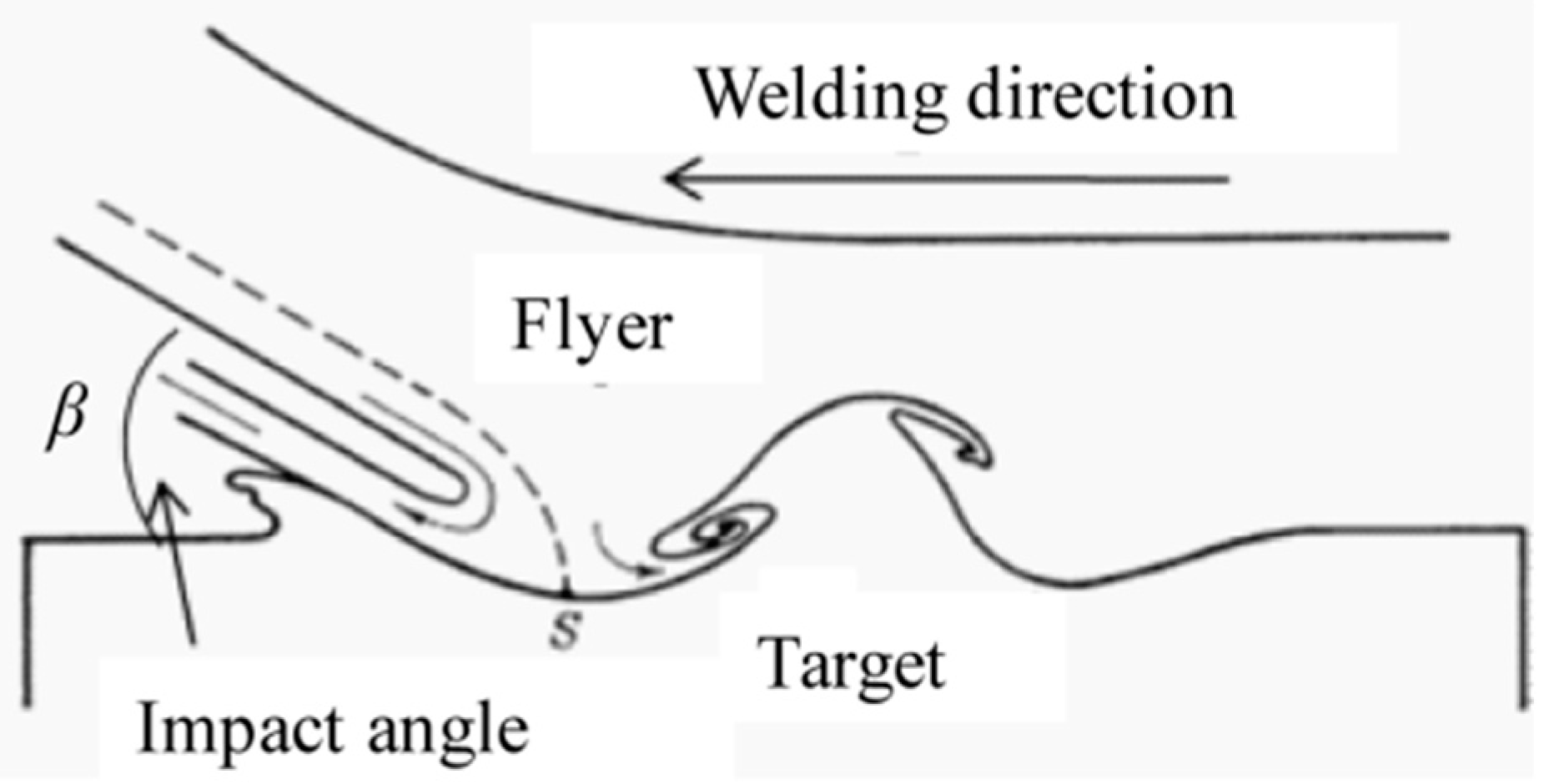

The welding cu to ss is accomplished by using al drivers to accelerate cu and ss work sheets.

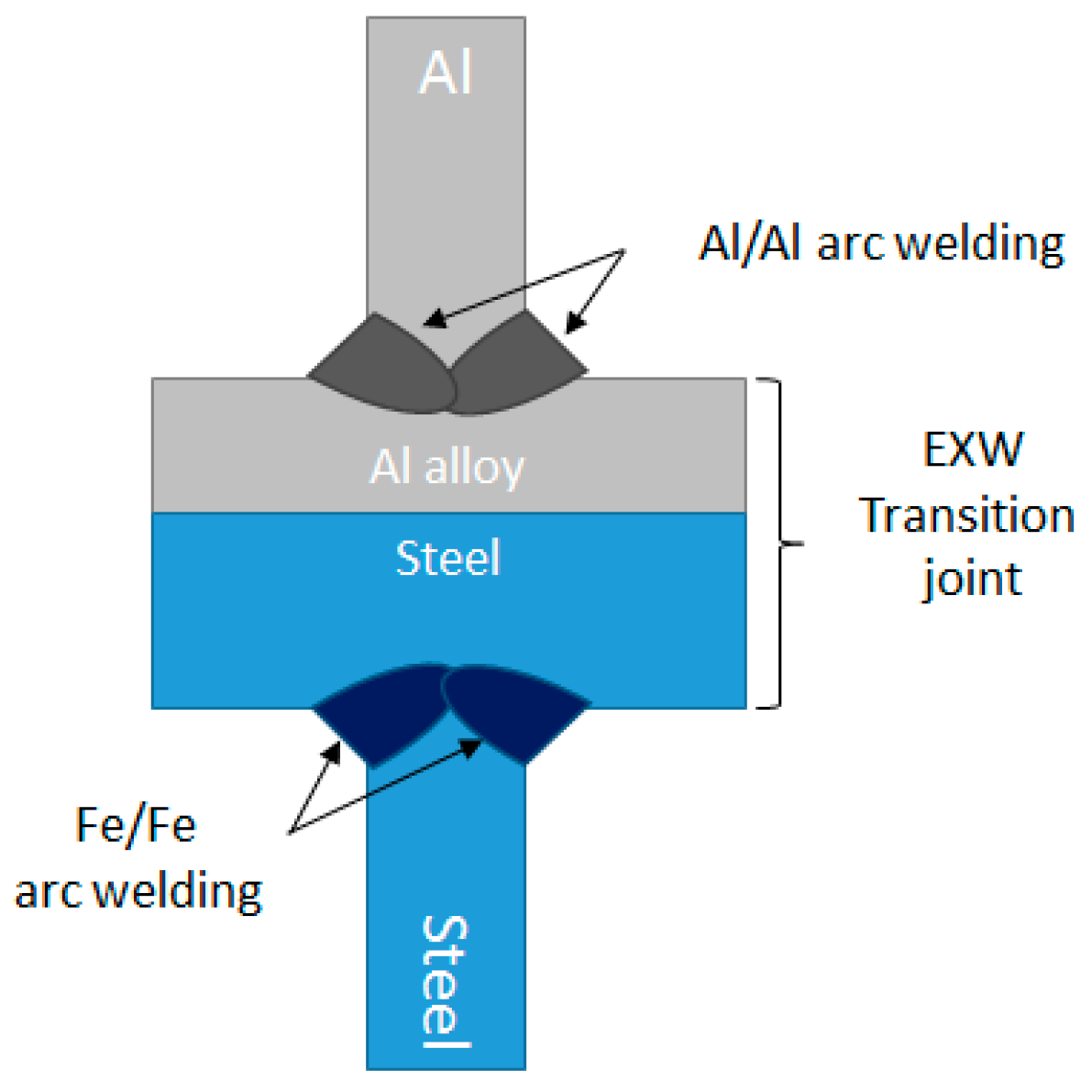

The processes which are available for welding of al to ss are friction welding laser welding electric discharge welding etc.

Welding of aluminum al to stainless steel ss is difficult due to the difference in their melting temperatures.

The welding cu to ss is accomplished by using al drivers to.

2008 made similar kind of observations when they successfully joined 1 mm al sheet with 0 25 mm stainless steel ss sheets using an aluminium plate as a driver for ss sheet.