Short video tutorial of modification flat feature in sheet metal mode or how to create custom edge treatment with flat feature in creo parametric 2 0 tags.

Edge treatment for sheet metal.

The model regenerates using the new settings.

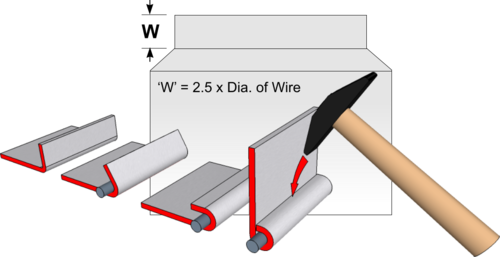

Sheet metal edge shapers make different edge styles on your sheet metal with these forming tools.

Burrs can arise during slitting.

There are many different techniques for forming a bead.

Hand held sheet metal edge shapers with a single tool create both sharp creases and soft curves along the edges of sheet metal.

Solid edge is designed by engineers for engineers and solid edge sheet metal is a fine example of this.

Solid edge uses this philosophy to generate sheet metal components which allows the engineer to think about the design and leave the laborious but nevertheless important details to solid edge.

0 5 thickness uses a default radius equal to half the thickness of the sheet metal wall.

Normally this results in a nick shiny and a break dull area on the slit.

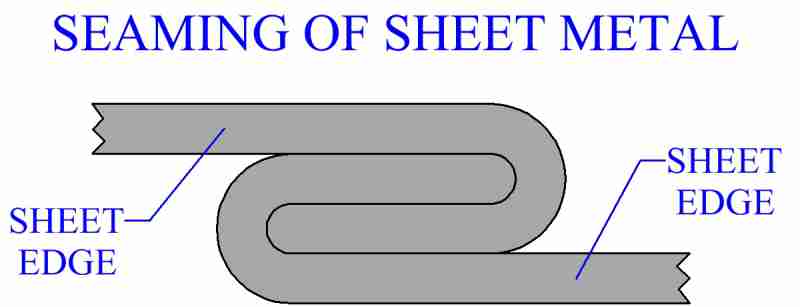

A hem is a flange that has been bent more than 180 degrees.

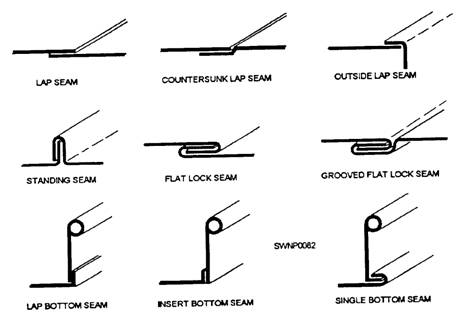

Beading forms a curl over a part s edge.

Hemming is used widely in sheet metal operations.

Beading is common in the edge treatment of sheet metal parts and can also be used to form the working structure of parts such as hinges.